Bruno Comby, President of

EFN, builds his ecological dream house* near Paris :

this high-comfort eco-house

requires 20 times less energy and divides by 200 the house's CO2

emissions (compared to a standard European house) !

An exemplary ecological house,

protecting nature, yet providing full modern comfort : highly

efficient ecological heating and air conditioning, constantly renewed

fresh air, regulated hygrometry, the environmentally perfect

dream-house...

* The words "dream house" are shamelessly

taken from the film comedy "Mr

Blandings builds his dream house"

starring Cary Grant and Myrna Loy. The film was a box office hit upon

its release in 1948.

Here is a photo of Bruno's ecological

dream house in construction, in March 2008

Here is a 360° panoramic view of

the ground floor in construction in April 2008

You can see on this panoramic view the

ventilation pipes going upwards to the upper floor, the highly

insulating windows and doors, the highly insulating red bricks (in

addition to rockwool for wall insulation three times more efficient

than usual). By looking closely, you wll also notice the thermal

bridge suppressors (polystyrene blocks at the horizontal junction

between the walls and roofs.

As an environmentalist, Bruno Comby wanted for his family a house

requiring as little energy as possible, yet that can be constructed

for an acceptable price, and that can be duplicated anywhere in the

world.

This house is the result of this dream.

The concept of the house chooses optimal construction methods in

each area and for each equipment for heating, ventilation, air

conditioning, and other equipments. The design of the house was

entirely done, the equipments chosen and their size and efficiency

precisely calculated by Bruno himself in such a way as to reduce the

energy requirement to the maximum possible extent, without

sacrificing modern comfort.

By taking care of the design and also part of the construction

work himself, Bruno maintained the cost of the house quite low,

similar and even lower than that of a standard (unefficient)

house.

The heating and air conditioning of houses and buildings are one

of the main sources of CO2 emissions in the world today. In France,

they represent 93 millions metric tons of CO2 per year, and 42% of

the energy consumption in the country. The primary energy need for

heating the existing homes in France are at an average value of 240

kWh/m2/year in 2007. It is possible, as this dream-house

demonstrates, to build homes that drastically reduce both the energy

requirement and CO2 emissions (up to 200 times less CO2 emitted than

a standard gas-heated home of the same size) simply by constructing

this type of long-lasting efficient homes and buildings that do not

emit (or almost don't emit) any CO2 and even that produce more energy

than they consume (positive energy houses).

The simple techniques that are to be used to reach this goal are

described below. By combining these different, simple and proven

techniques into the same house, as this dream-house shows in Houilles

(a typical suburb of Paris, similar to te surroundings of any large

city in the world), the energy requirement of our homes can be very

much reduced, to almost nothing.

This dream-house can be duplicated and constructed almost anywhere

(there may be just some minor differences to adapt this dream house

to each type of geographical and geological situation and type of

house desired).

Thermal losses of a typical house (source

ADEME)

Heating, ventilation and air conditioning (HVAC) of houses,

apartments and offices is one of the main sources of CO2 emissiosn in

France as elsewhere. We have the technology at hand to build

dwellings and office buildings which emit almost no CO2. Bruno has

put together a number of these technologies, as we shall show

below.

Here is a partial list of some simple and ecological HVAC building

technologies which he used to build his ecological dream-house at

Houilles near Paris. These reduce the energy consumption by a factor

20 or so, and reduce the CO2 emission by a factor 200, as compared to

gas heating currently being installed in new contruction in

France.

- at the level of planning: minimize the outer surface of the

construction, where heat is exchanged with the surrroundings, by

making the house compact, as near as possible to a cube or sphere

(this house is a cube); and orient it so that the main windows are

toward the south. In winter the sun will contribute to heating the

house and in summer awnings or shutters will keep the sunlight and

direct heat from entering. Plan for thick walls - the thicker the

wall the better it is an insulator, no matter what the material.

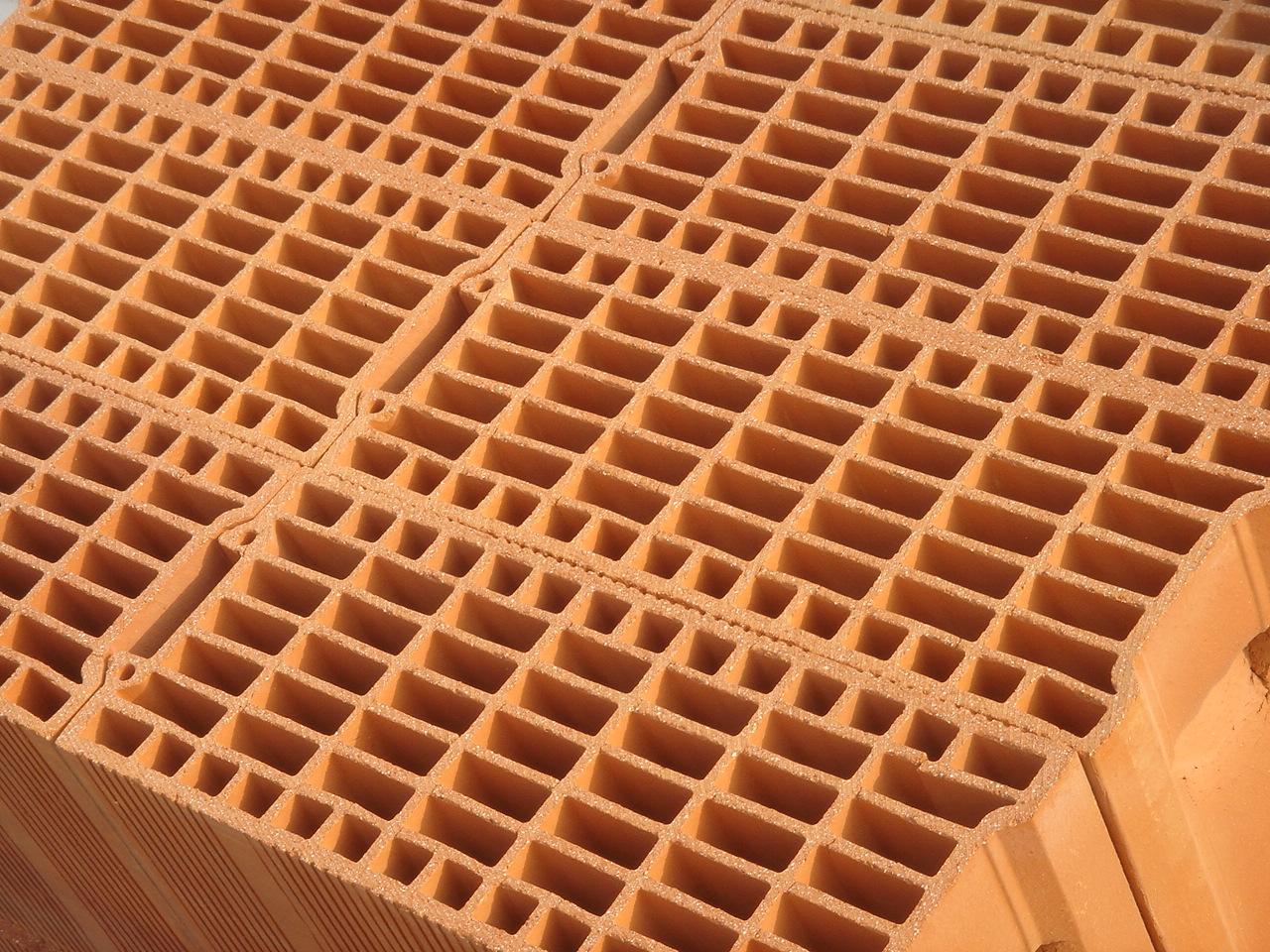

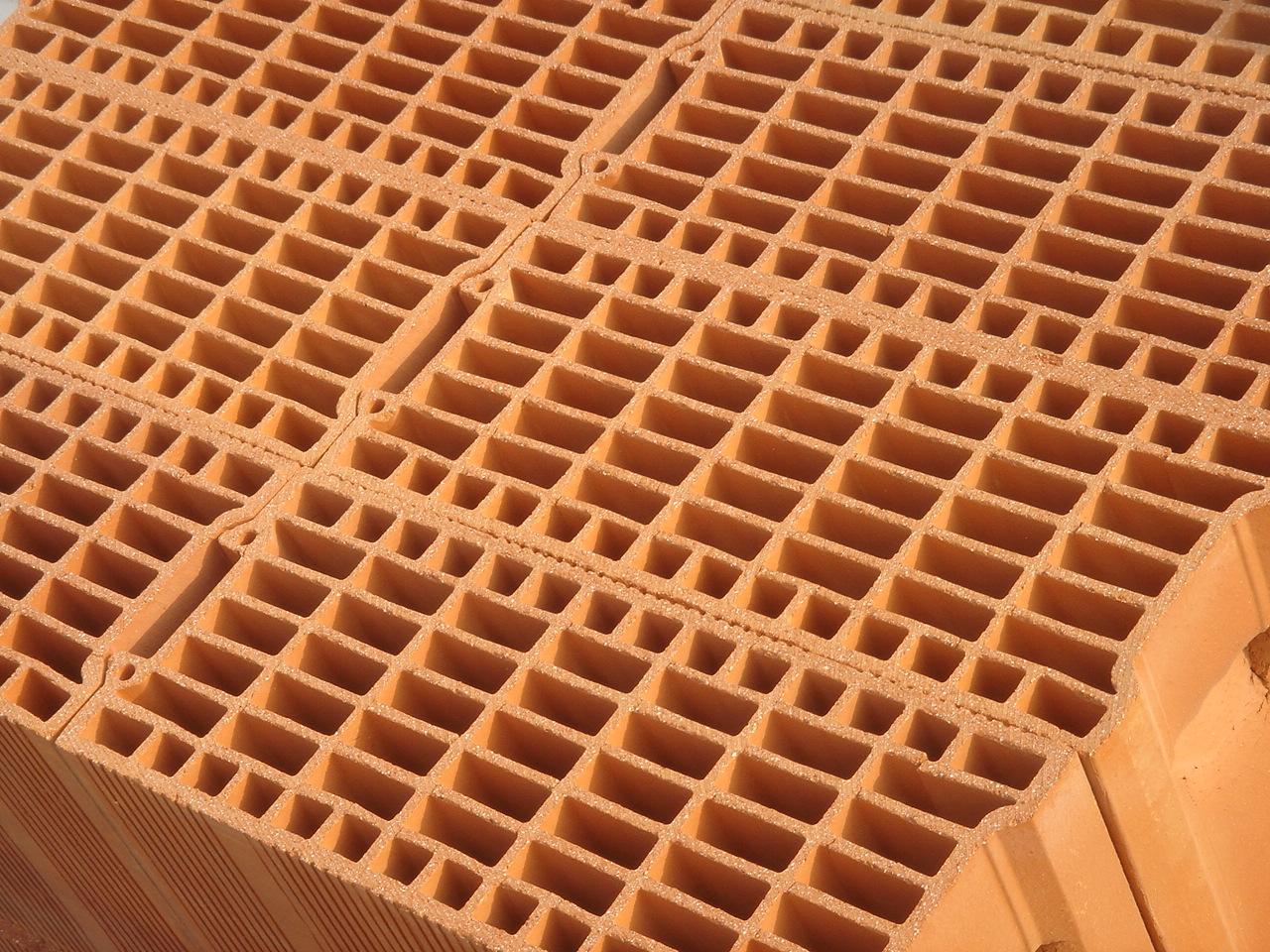

- choice of building materials: prefer long lasting insulating

material such as insulating bricks, and cellular concrete like

Siporex (low density concrete) or Insulating bricks that are 5 times

better than classical cinder blocks for the same wall thickness, and

they cost about the same. Insulating bricks moreover have greater

mechanical strength and the mason can build more rapidly with them.

French and European suppliers of insulating bricks include

Wienenberger's Porotherm,

thermopierre (formerly Siporex) sold by

Xella,

monomur

bricks, and Bouyer-Leroux's brique

Thermo BGV . Bruno has chosen to build with Thermo BGV which have

the greatest thermal efficiency (BGV = Briques à Grande

Vitesse "high-speed bricks" because the construction is done in much

less time using these bricks than standard concrete construction).

Click

here to go to the bottom of the page to

see a video and practical instructions for building a wall with these

BGV insulating bricks.

Here are a few snapshots of the ecological

house Bruno is

building:

(photos B.C.)

|

A pallet of insulating bricks has just arrived. They have

a vertical alveolar structure - type BGV - highly insulating

and easy to build with.

|

Using a laser to level the first row of bricks accurate

to a millimeter. Since the joints are very thin, the first

layer of bricks must be perfectly level.

|

Using a straight-edge to prepare the bed of mortar before

laying the first layer of bricks - it must be perfectly

level and flat.

|

|

Then the mason can lay the bricks very quickly.

|

The second layer of bricks.

|

The wall goes up quite fast; it takes little more than a

day to complete each floor.

|

|

Terra cotta bricks can be cut with an alligator saw.

|

At the level of the intermediate floor slab, the

planelles de rive vertical

bricks on the exterior (in contact with outside

temperatures) are also insulating. This reduces the heat

loss and "thermal bridges" at this level

|

Et voilà le travail !

|

You may click here to see more

of the snapshots taken while we were putting up our ecological

house with THERMO BGV insulating bricks (Briques à Grande

Vitesse - high speed bricks [apologies to SNCF for copying the

TGV, the French high speed Train à Grande Vitesse])

See this video

of putting up a wall of insulating bricks. showing all the clever

tricks of the brick manufacturer, Bouyer-Leroux.

- be sure to make air-tight joints between the masonry walls and

the windows, doors, rolling shutters, and all. If this phase of the

work is properly executed, you will save a lot of energy over the

whole life of the building. Air-tight joints are a simple thing to do

and an important element of a highly efficient home. There is no

point in building a highly efficient home if the joints aren't done

properly (beware of small details).

- break the horizontal thermal bridge where the floors touch the

outside walls. Concrete is an excellect heat conductor; in

traditional construction with concrete floors, each floor is

effectively a radiator of cold, bringing the outside cold into the

warm building through the floors. So are partitions in contact with

the outside walls. To cut this thermal connection one need only lay

down blocks of polystyrene at the outskirt of each floor before

pouring the concrete slab for each floor. The extra cost of

construction is nil or negligible, but the consequent energy savings

are substantial. Unfortunately this is impossible to do in a

renovation. Here are a few snapshots of polystyrene blocks installed

in our ecological house. (Notice the very thin joints between the

bricks to avoid heat heat losses through the joints.)

|

Breaking the thermal connection at the floors. One simply

inserts an insulating block, polystyrene in this case, at

the floor level to prevent the concrete slab from touching

the outside of the building thus preventing cold from

penetratating into the dwelling space.

|

There are two types of polystyrene blocks to break the

thermal connection. : those who are perpendicular to the

concrete beams and those who are parallel to the beams.

|

The technique of breaking the thermal links implies

negligible cost, yet it is little used even in new

construction where it could be most easily applied. Click to

see the KP1's isorupteurs

KP1.

(photos B.C.)

|

To improve the thermal performance of old buildings (renovation)

and suppress the thermal bridges in these existing homes or

buildings, the best solution is external insulation (but it is not as

long-lasting). One might call it an "overcoat wall". It consists of

surrounding the building with a layer of insulating material added on

the outside of the wall, such as, for example, polystyrene associated

with a more rigid wall material &endash; say fiberglass or thin

bricks. See : http://www.frog3.com/jpb/isolationext.htm,

zolpan,

mur

manteau

Windows

For

the windows we have chosen frames made of PVC, an inexpensive plastic

material which requires no maintenance (painting) and which insulates

better than wood and much better than aluminium. The windows have

double glazing with argon gas between the two panes; this improves

the thermal performance by about 10%. The window panes have a surface

treatment conferring enhanced insulation. It consists of depositing

an ultra-thin and invisible metallic coating on the glass when it is

manufactured. See http://www.uf-pvc.fr/metier/?rub=infotech_thermique.

That thin coating reflects infra-red light and helps to keep that

energy inside the house, but it lets ultra-violet light (sun light)

coming from outside get through. This improves the thermal behaviour

of window glass by about 40%. The additional cost for argon gas and

surface treatment of the glass is quite inexpensive&endash; a few

Euros per square meter for an improvement of 50% in the insulating

quality of the window as compared with a classical double glazed

window. This helps do away with the "cold wall" effect of windows and

avoids condensation. These highly efficient windows obtained by

depositing a thin metallic layer are expected to become legally

required in France in the future. (photos

Rights Reserved.)

For

the windows we have chosen frames made of PVC, an inexpensive plastic

material which requires no maintenance (painting) and which insulates

better than wood and much better than aluminium. The windows have

double glazing with argon gas between the two panes; this improves

the thermal performance by about 10%. The window panes have a surface

treatment conferring enhanced insulation. It consists of depositing

an ultra-thin and invisible metallic coating on the glass when it is

manufactured. See http://www.uf-pvc.fr/metier/?rub=infotech_thermique.

That thin coating reflects infra-red light and helps to keep that

energy inside the house, but it lets ultra-violet light (sun light)

coming from outside get through. This improves the thermal behaviour

of window glass by about 40%. The additional cost for argon gas and

surface treatment of the glass is quite inexpensive&endash; a few

Euros per square meter for an improvement of 50% in the insulating

quality of the window as compared with a classical double glazed

window. This helps do away with the "cold wall" effect of windows and

avoids condensation. These highly efficient windows obtained by

depositing a thin metallic layer are expected to become legally

required in France in the future. (photos

Rights Reserved.)

Insulating front door and garage

door

There are many manufacturers and many models of doors. Some doors

are more insulating than others and the best insulated ones are not

necessarily the most expensive. We have chosen a door of steel on

both surfaces with foam between the two steel plates. It is better

insulating and more solid, it better resists break-in, requires no

maintenance and costs the same as a door made of wood which are

chosen in France by most of the new home-owners by tradition,

although they are less efficient, more expensive, more fragile

mechanically, will not last as long, require being repainted every

few years and are thermally less-efficient.

Wall insulation

There are different systems of insulation. We have chosen St

Gobain's OPTIMA quality GR 32. Its coefficient of insulation is about

30% greater than traditional glass wool, for the same thickness. This

system is about twice as insulating as the 8 cm of polystyrene

habitually installed in most new construction in France these days.

Added to the insulating power of the insulating bricks, we have about

3 times less loss of heat through the walls.

Double-flux ventilation

Instead of heating the atmosphere by exhausting warm air from the

house, the double-flow ventilation (DFV) recovers the heat of

the warm out-going air and transfers it to the intaken air (whence

the term double-flow). This is accomplished by a heat exchanger

consisting of a system of metallic plates. The yield approaches 95%,

that is, 95% of the heat in the exhaust air is transferred to the

intaken air. Installing a DFV system adds a few thousand Euros to the

cost of the house but leads to significant savings of energy as well

as improved comfort. Air flow can be controlled and the air is

filtered and thus of better quality. For his ecological house, Bruno

has selected the DFV

Hélios type KWL EC 450 Pro plant providing up to 450 cubic

meters per hour of pure, filtered and preheated air which enters

through the puits canadien (see below). At 300 cubic meters

per hour, which is quite adequate, and running 24 hours a day, the

DFV will consume 50 watts, and cost about 40 euros a year (and I

remind you that in France electricity is over 90% nuclear and emits

very little CO2).

Puits

canadien (earth cooling/warming tubes)

Puits

canadien (earth cooling/warming tubes)

The principle of the puits canadien &endash; to preheat

intake air in winter &endash; or the puits provençal

&endash; to cool intake air in summer &endash; consists of passing

the intake air through pipes buried about 2 meters underground before

it enters the house. At that depth the temperature is very nearly

constant all year 'round &endash; about 14 degrees C. So it is

possible to preheat the intake air in winter, up to about 14 degrees,

and correspondingly to cool the intake air in summer, providing air

conditioning gratis. For an adequate flow of air, the tube

ought to be 15 to 20 cm in diameter and 50 to 100 meters long. A 50

watt electric fan will provide an adequate air flow for a large

house. Click here

for a complete photo report on the our installation of Bruno's

puits canadien in the Paris region .

Heat

pump for the heating

Heat

pump for the heating

This allows us to heat a dwelling with 3 to 6 times less

electrical energy. Heat pumps operate in various ways pumping heat

from inside the earth around a building, to distribute it inside the

house (low temperature floor heating). At the right you see a photo

of the Viessman Vitocal 300 heat pump which Bruno has chosen for his

ecological house. It extracts geothermal heat from underground. The

heat pump is about the same size as an ordinary gas furnace but it

consumes only electricity, and not much electricity at that: its COP

(Coeffient Of Performance) is 6 which means that is consumes 6 times

less electricity than electric resistance heating, for a given amount

of heat produced. In France, in addition, over 90% of the electricity

is generated without production of CO2, so such a heat pump is very,

very friendly to the environment. The heat pump also produces the hot

water for bath and kitchen, with a COP of about 3.5; much better than

the COP of solar hot water heating which is about 2 or 3 in the Paris

area, requiring much less electric resistive

boosting

Conclusion

Combining these construction methods and technologies in the same

house, reduces the heat requirement by a factor of 5, the energy

consumed by a factor of 20 and the carbon dioxyde emissions by a

factor 200 (in France), compared to a standard construction

satisfying the most recent European regulations now in application

(RT 2005).

For Bruno's ecological

house, the heat pump, the HVAC unit , the

double-flow ventilation and its heat exchanger (DFV) as well as the

entry of the external air through the puits canadien are

grouped together in a small room situated in the basement.

Such a house with all modern comforts should cost no more than 100

Euros per annum for winter heating, with air conditioning thrown in

gratis. It will require practically no maintenance &endash; neither

logs to put in the fireplace nor ashes to sweep out, neither burners

to regulate nor the obligatory annual chimney sweeping. It will emit

virtually no CO2 &endash; about 200 times less than the same house

built to modern standards and gas heated. Everything inside the house

has been optimized to be thermally efficient.

This is an ecologist's

dream house which has come true !

We would like to emphasise that all the techniques and

technologies used by Bruno are available and are or can be

mass-produced.

This optimised ecological dream-house takes advantage of all these

techniques and technologies in order to minimise its energy

requirements to the greatest possible extent. This house exists

&endash; in Houilles, a close suburb of Paris. To our knowledge it is

the only house in the world to achieve this level of energy savings

and comfort.

For additional information, to learn more about the energy

requirements and the performance of this ecological dwelling, to find

the tools and the software to calculate and simulate the thermal and

energy performance of your own house, visit our "blog

de la maison écologique" (in French, see http://babelfish.yahoo.com/

for a free translation of this web page) or come visit the house

under construction.

To visit this ecological house, join

EFN and come see the house or participate in the annual general

meeting of EFN (next annual meeting in Houilles on saturday 13th

december 2008). Journalists can contact EFN (Environmentalists For

Nuclear Energy) at: +33 1 30 86 00 33.

See our blog on this ecological construction project at http://comby.blogspot.com

(see http://babelfish.altavista.com/

for a free translation of this page).

Don't hesitate to contribute to these blogs by clicking on

comments. Your words will be automatically published on the internet

and will help inform the visitors who follow you. (No advertising,

please. Insults and disagreeable passages will not be published. On

the other hand, we welcome additional information and civil

opinion.)

For

the windows we have chosen frames made of PVC, an inexpensive plastic

material which requires no maintenance (painting) and which insulates

better than wood and much better than aluminium. The windows have

double glazing with argon gas between the two panes; this improves

the thermal performance by about 10%. The window panes have a surface

treatment conferring enhanced insulation. It consists of depositing

an ultra-thin and invisible metallic coating on the glass when it is

manufactured. See

For

the windows we have chosen frames made of PVC, an inexpensive plastic

material which requires no maintenance (painting) and which insulates

better than wood and much better than aluminium. The windows have

double glazing with argon gas between the two panes; this improves

the thermal performance by about 10%. The window panes have a surface

treatment conferring enhanced insulation. It consists of depositing

an ultra-thin and invisible metallic coating on the glass when it is

manufactured. See  Puits

canadien (earth cooling/warming tubes)

Puits

canadien (earth cooling/warming tubes) Heat

pump for the heating

Heat

pump for the heating