|

|

EFN -

NEWS

Newsletter of

EFN

Environmentalists

For Nuclear Energy

11th

August 2004

|

This document is archived on

the internet and can be consulted at the following address:

http://www.ecolo.org/archives/archives-nuc-en/

New e-mails for writing to

EFN: scroll to the bottom of this page

Causes

of the industrial accident at Mihama in Japan

by Bruno Comby

Photo

of the Mihama nuclear power plant seen from the nearby beach. The

accident took place in the turbine hall of reactor number 3 which is

the one on the right of this photo.

Photo

of the Mihama nuclear power plant seen from the nearby beach. The

accident took place in the turbine hall of reactor number 3 which is

the one on the right of this photo.

© Photo EFN - www.ecolo.org /

Bruno Comby (April 2001)

Dear readers, dear friends,

Following the accident which occurred two days ago

at the Japanese nuclear power station at Mihama, please find below

some information about this event.

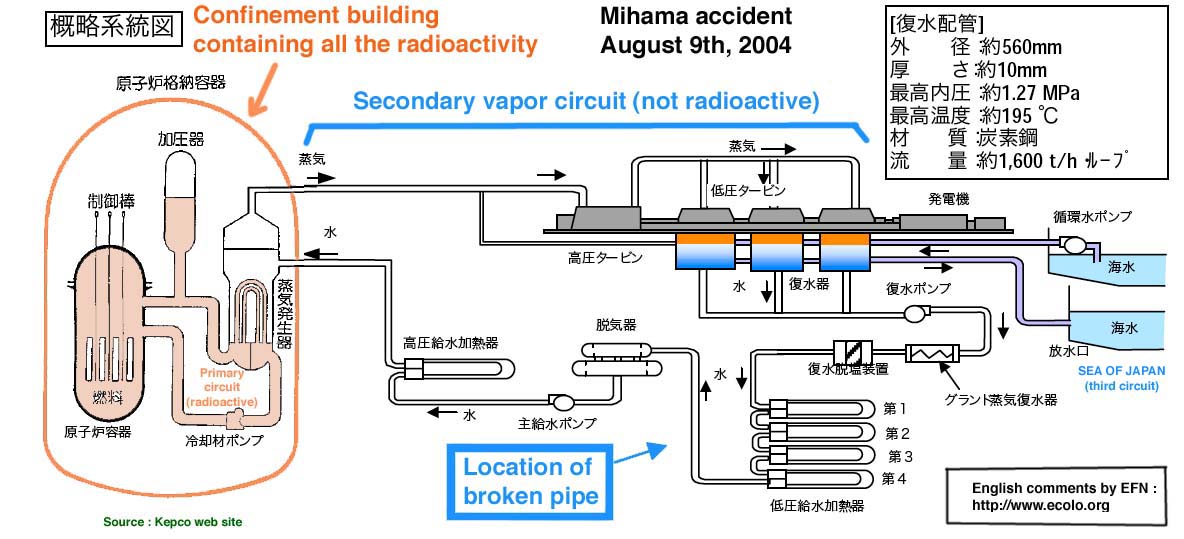

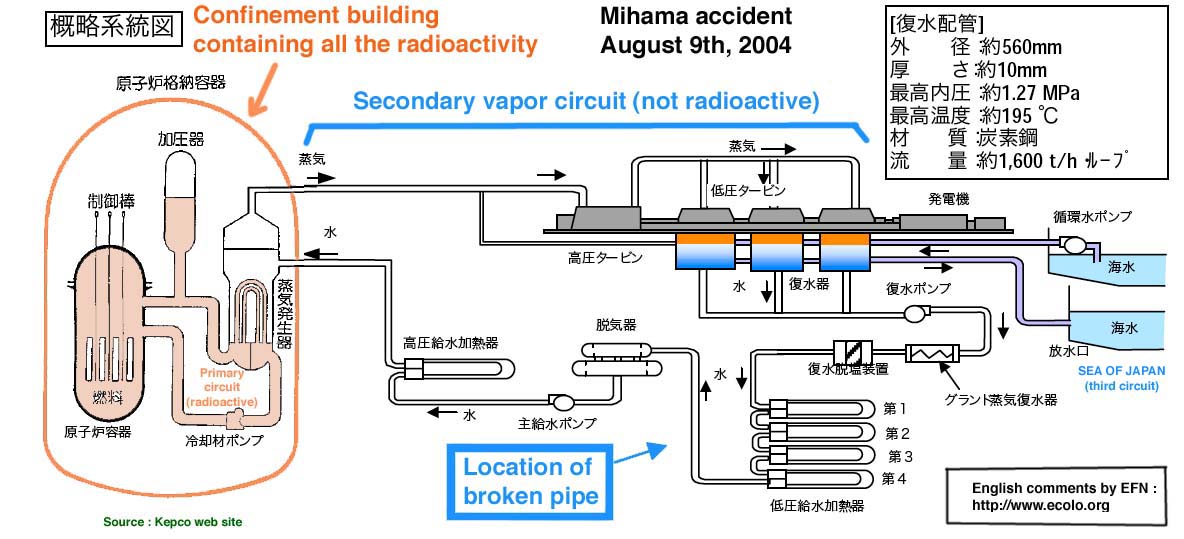

The cause of that accident was the suddden rupture

of a pipe carrying pressurized water in the secondary circuit of the

power station, after it had passed through the turbine and heat

exchanger and before it returned to the steam generator (see

photos

and the schematic of the

circuit below). In an instant, the pipe

broke, and an enormous burst of steam was released into the turbine

hall.

Eleven persons who were in the turbine hall at

that moment were seriously burned (scalded). Four of them died the

very day of the accident. At least two of the other seven are in a

critical state and their prognosis is not favorable.

The rupture occurred in a straight part of a black

steel tube 56 centimeters (22 inches) in diameter

carrying pressurized water.

When the reactor was at full power, that steam

would have been at a temperature of 195°C, under a pressure of

12.7 atmospheres (about 180 psi); we have been told that, at the

moment of the accident, the temperature was 140°C and the

pressure 9 atmospheres, but that information is yet to be

confirmed.

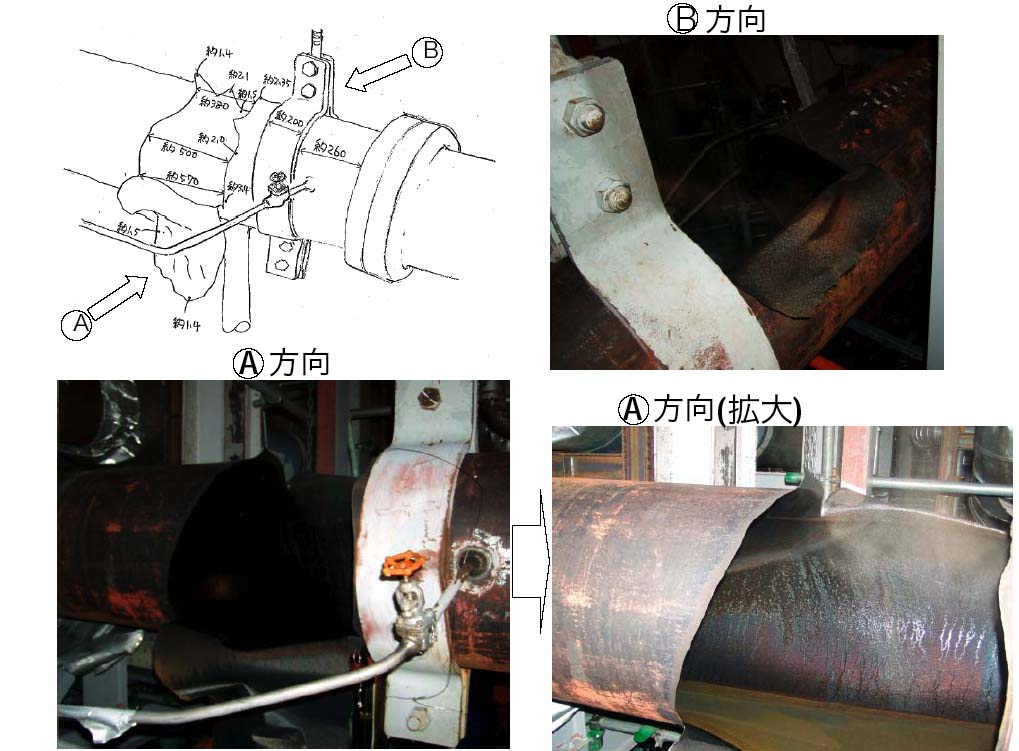

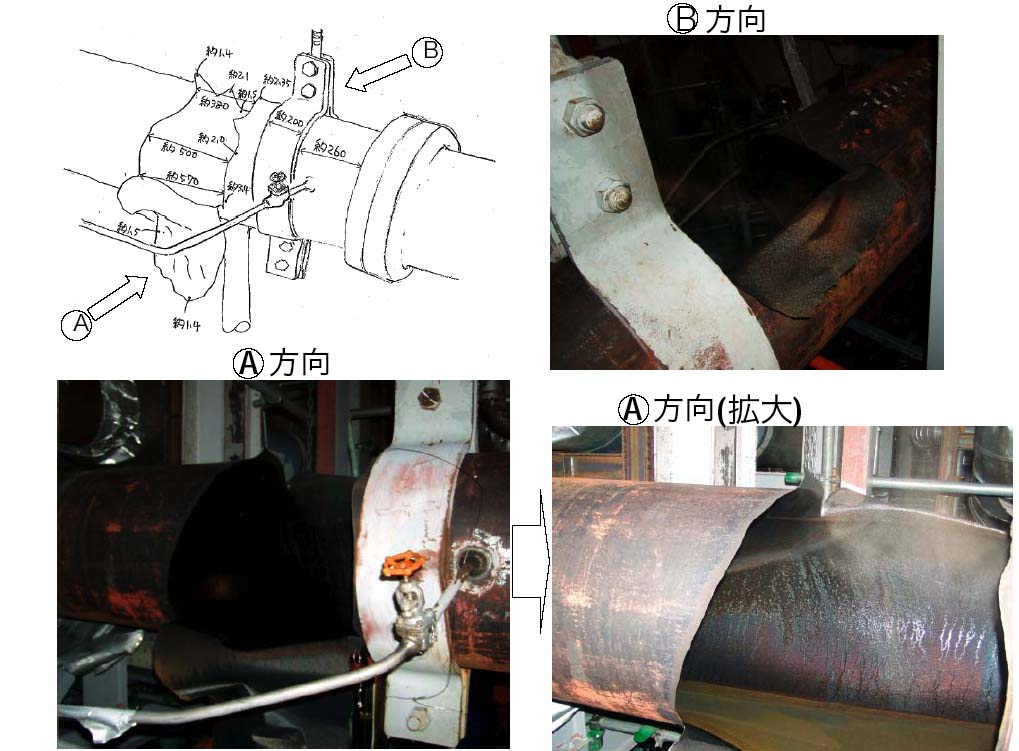

When the power station was built, the wall of the

tube was 10 mm thick (0.4 inch), and it was supposed to remain at

least 4.7 mm thick to stay safe; but, as one can see from the photo

below, it was almost entirely eroded and down to 1.4 to 1.5 mm thick

in a large area around the rupture zone. There was a great deal of

corrosion. This reflects a major fault, either at the stage of

engineering design, where the phenomenon of corrosion was

under-estimated or neglected (similar pipes in more recent nuclear

power plants are now in stainless steel, not black steel); or in the

inspection routine. Periodic inspections, correctly carried out using

ultra-sound instruments currently in wide use, would have revealed

the weakened state of this tube.

The Mihama-3 reactor, a Mitsubishi pressurized

water reactor of 826/780 MW(e), diverged in January 1976 and was

connected to the grid on 19th February 1976. It has thus operated for

28 years and should have been the subject of at least two major

inspections. Major inspections on nuclear power plants are usually

performed every 10 years. These inspections are particularly

detailed. How could they not have detected this defect? According to

today's news broadcast on the Japanese television, but yet to be

confirmed, this pipe had not been verified even once since the

reactor was put into operation. It seems then that there have

been one or several instances of severe incompetence.

During a press conference held at Mihama, 350 km

west of Tokyo, Koji Ebisuzaki, director of quality control,

said "We are responsible" Haruo Nakano, spokeman for KEPCO,

the utility which owns and operates the plant, declared "We made

visual inspections but never used ultra-sound." Ultra-sound

inspections on this tube were not obligatory, but thaere is no other

way to detect internal corrosion of such a tube. KEPCO had recently

put off an in-depth technical evaluation of the very tube which

failed. The inspection of this tube had been planned and should have

been performed several months earlier, but KEPCO had decided to

postpone this verification until the next inspection.

EFN reminds the world and insists upon the

point that maintenance and safety in nuclear power stations are and

must remain absolute priorities.

We note however that even though several mistakes

were committed at different levels: the pipe was in black steel that

corrodes easily, the corrosion was not checked, the Japanese safety

authorities new that this pipe needed to be changed (several had

already corroded and had been replaced by stainless steel pipes in

other Japanese nuclear power plants), and above that the inspection

which was planned (too late) was postponed, the basic principles of

nuclear safety nevertheless still played their role effectively to

prevent from a larger accident: the multi-level and redundant safety

systems installed at different levels shut the reactor down

automatically and immediately without any other incident, despite the

extremely rare character of the event and the gravity of the

situation.

Yesteday's news bulletin mentioned steam at 260 or

270°C. That would be the temperature at the exit of the steam

generator, before passing through the turbine and condenser; but it

was not there that the rupture occurred. At the site of the rupture,

after the turbine and condenser, the temperature would be lower but

still high enough to inflict serious burns on the unfortunate men

working nearby in the turbine hall.

The nuclear reactor shut down spontaneously at the

moment of the accident, but it is not clear at this moment whether it

was the rupture of the tube which caused the emergency shutdown of

the reactor (which is the most likely scenario), or whether some

other event led to the automatic shut down of the reactor, causing an

overpressure itself causing the corrosion-weakened tube to

fail.

We wish to repeat that absolutely no radioactivity

was released into the environment. The accident was not nuclear but

industrial - it could have happened in any power station whether

heated by nuclear energy or by burning fossil fuel.

With four victims (to date), this is a tragic

event. In fact, it is the worst accident to have occurred in a

nuclear power station since the Chernobyl accident of 1986. But we

must view things in perspective: recent news items have shown us once

again that natural gas is a killer, causing many fatal incidents and

killing many more persons each year; not to speak of the thousands

who die every year in coal mine accidents without getting the same

attention from the media.

The flow in the secondary circuit of the power

station, is about 1600 tonnes of water per hour, about 27 tonnes per

minute, or, if you like, nearly a tonne every two seconds. And this

under a pressure of about ten atmospheres. When the pipe ruptures

like this, the pressure is reduced and the water (140°C)

transforms into steam, is projected until it fills the entire

machinery hall. Our brief calculation suggests that it would take

only a couple of minutes to fill a hall of dimensions 100m x 50m x

20m, unless the leaking pipe could be isolated and the flow of steam

stopped.

The ruptured circuit was isolated, and the steam

projections stopped indeed after some time (how much? we don't know).

According to information published by the Japanese media (asahi.com),

there were 220 subcontractors (which is a lot) working inside the

plant (how many of them in the turbine hall when the accident

occurred? we don't know). The subcontractors were preparing a planned

inspection which was about to start a few days later.

The 11 workers who were scalded seem to be those

who were nearest to the pipe when it broke. Some of them had severe

body burns because they received bursts of steam directly on their

bodies, and others badly burned their lungs by breathing the hot

steam as it spread throughout the turbine hall. Four have already

died and seven of them are now struggling for life in the Fukui

prefecture hospital. One of them is severely burnt on 80% of body

surface, and will certainly not survive, and several others are in

critical condition. Luckily, some workers managed to escape the

turbine hall safely (how many? we don't know).

Hot pressurized water and steam are

dangerous. In bygone days, industrial and

domestic boiler and hot-water heater accidents were frequent, often

involving equipment which was badly adjusted, badly maintained and

without adequate safety systems. Many victims were scalded (burnt by

steam) and many died of their burns. Sometimes it was faulty

equipment, but often it was imprudence. For example, in steamboats

navigating the Mississippi River a century ago, it was not uncommon

to tie down the safety valves, especially in a boat race, or just to

let the pressure rise higher, forcing the boat at a higher speed. In

one case, on the Mississipi river in 1865, a steam explosion is said

to have killed 1,547 people, many of whom were prisoners being

trasferred, when the steam boiler powering the boat suddenly

exploded. Many were scalded and died from the explosion itself, and

others drowned. Nor were industrial boiler explosions rare. Since

then, safety standards have been imposed and progressively tightened.

In the United States, there is a long standing National Board of

Boiler and Pressure Vessel Inspectors whose standards and rules are

accepted world-wide. Chemical engineers are particularly alert to

these questions. Nevertheless, steam burns and boiler explosions

still kill frequently. Numerous references are obtained for example

by searching for "boiler explosion" on the internet.

In any event, as the Mihama accident reminds us,

there is no energy without risk, and hot pressurized water (whether

produced in a nuclear reactor or not) is dangerous and should be

handled with precaution. Accidents are always possible, and we must

be extremely vigilant and prudent to create and strengthen a culture

of safety and meticulously respect the rules. Although rarer than

before, industrial accidents due to corrosion of pipes and steam

explosions still occur, but they are hardly mentioned in the media,

when they occur in places other than nuclear power plants.

What would be the impact of an accident as serious

as Mihama, if it had occurred in any plant but nuclear? Perhaps an

article in the local or regional paper, an item on the evening TV

news, but it would certainly not receive the honors of notice in the

international press as Mihama does these days.

On the one hand, we should learn from this sort of

experience and do everything to avoid the recurrence of accidents

like Mihama. In case such an accident does occur, we must be able

limit the damages by prevention.

On the other hand, we must emphasize the

NON-NUCLEAR nature of this accident, which might have occurred in any

other factory or in a power plant fired by gas or coal or oil. It was

not a NUCLEAR accident. It was an INDUSTRIAL accident.

Greenpeace and other ecological movements around

the world have already begun in their own shameful way to take

advantage of this unfortunate accident, and to demand once again that

the world abandon nuclear energy, in Japan and elsewhere. They are

not impressed by the fact that THE ACCIDENT AT MIHAMA WAS NOT A

NUCLEAR ACCIDENT. Recent gas explosions have had many more victims

than Mihama, but we don't hear these associations calling to "stop

gas" or for a "gas-free world" comparable to the "stop nuclear" or

"nuclear-free world" shoutings which re-appeared today in reaction to

this unfortunate INDUSTRIAL (NOT NUCLEAR) accident. Explosions are

rather a speciality of gas, you know; they cause more frequent and

bigger accidents, with many more victims than yesterday's accident in

Japan. Is there any consistency in their behavior?

EFN extends its most sincere condolance to the

families of the victims.

Sincerely yours,

Bruno Comby

President of EFN

Environmentalists For Nuclear Energy (civilian only, properly used,

and with the greatest of precautions)

On

this photo taken on August 9th, 2004, one can see the steam rising

from the turbine building of reactor number 3 at the Mihama Nuclear

Power Plant in Fukui Prefecture. That steam comes from the inside of

the turbine hall,.which is the rectangular building on the left hand

side of the photo. The reactor itself containing the nuclear fuel is

located inside the circular-shaped concrete confinement in the center

of the photo. The nuclear reactor, the confinement building, and the

primary circuit were not affected at all by the accident. Mihama was

not a nuclear accident. The nuclear part of the installation was

unaffected. No radiation leaked and the reactor itself always

remained safe and under control.

On

this photo taken on August 9th, 2004, one can see the steam rising

from the turbine building of reactor number 3 at the Mihama Nuclear

Power Plant in Fukui Prefecture. That steam comes from the inside of

the turbine hall,.which is the rectangular building on the left hand

side of the photo. The reactor itself containing the nuclear fuel is

located inside the circular-shaped concrete confinement in the center

of the photo. The nuclear reactor, the confinement building, and the

primary circuit were not affected at all by the accident. Mihama was

not a nuclear accident. The nuclear part of the installation was

unaffected. No radiation leaked and the reactor itself always

remained safe and under control.

Photos of the scene of the

accident and ruptured pipe : source KEPCO - Kansai Electric Power

Corporation (August 10th, 2004)

Bruno Comby, EFN founder and

president (http://www.ecolo.org

), is the author of 10 books published in 15 languages on ecology and

energy, including the bestseller "Environmentalists

For Nuclear Energy"

(published by TNR

Editions). He is a

graduate of the Ecole Polytechnique in France, and holds a

postgraduate qualification as nuclear physicist from the Superior

National University of Advanced Technology in Paris

(ENSTA).

Copyright notice : you are

authorized (and encouraged) to distribute, translate and/or publish

the text above freely, in paper or electronic form, and to send it to

the media for publication, with the authorization to be published,

under the condition that : 1/ it is republished or transmitted as is,

without any modification (other than minor editing) 2/ you send a

copy of the published article(s) to: EFN[at]ecolo.org 3/

translation(s) be sent to EFN for reviewal before publication, such

translation(s) may be posted on EFN's web site and/or to EFN's

mailing lists. If substantial modifications (other than minor

editing) are required such as adding comments or making significant

changes to the text, please contact EFN.

New

e-mails for writing to EFN

To write to EFN, please use the following e-mail

addresses, and your messages will be sent directly to the adequate

correspondent:

Contact for North America :

nuc-us[at]ecolo.org (Environmentalists For Nuclear Energy)

Contact in English language :

nuc-en[at]ecolo.org (Environmentalists For Nuclear Energy)

Contact in French language :

nuc-fr[at]ecolo.org (Association des Ecologistes Pour le

Nucléaire)

Contact in Japanese language :

nuc-jp[at]ecolo.org

To write to Bruno Comby (President of EFN) :

New e-mail : bruno[at]ecolo.org. Update your files. From now

one, please do not use this old address any more : [email protected],

this address is to be deleted from all your files. It will be dropped

in a few days.

To write to Berol Robinson (President of EFN-USA :

berol[at]ecolo.org

Berol

is the President the American association of Environmentalists For

Nuclear (EFN-USA) http://www.ecolo.org/base/baseus.htm

; this association was incorporated in the State of Delaware. EFN-USA

is distinct from EFN-EUROPE, and operates as an organization with

similar activities and for the same purpose (informing the public on

energy) but in the United States. EFN-USA was recently approved by

the IRS as a tax-exempt 501(c)(3) not-for-profit corporation,

authorizing tax-deduction of your donations (click on the American

flag on the home page http://www.ecolo.org and then on "subscribe" or

"donation" in the menu. You can make a donation by check, credit card

(paypal) or bank transfer, as indicated. EFN-EUROPE is also a

tax-deductible organization in France.

Berol

is the President the American association of Environmentalists For

Nuclear (EFN-USA) http://www.ecolo.org/base/baseus.htm

; this association was incorporated in the State of Delaware. EFN-USA

is distinct from EFN-EUROPE, and operates as an organization with

similar activities and for the same purpose (informing the public on

energy) but in the United States. EFN-USA was recently approved by

the IRS as a tax-exempt 501(c)(3) not-for-profit corporation,

authorizing tax-deduction of your donations (click on the American

flag on the home page http://www.ecolo.org and then on "subscribe" or

"donation" in the menu. You can make a donation by check, credit card

(paypal) or bank transfer, as indicated. EFN-EUROPE is also a

tax-deductible organization in France.

Please receive our ecological salutations and best

wishes for the end of the summer season !

http://www.ecolo.org

EFN - For complete and

straightforward information on energy and the

environment

To subscribe (or unsubscribe) to EFN's mailing list, go to EFN's

web site : http://www.ecolo.org

and click on "mailing list".

You may, with their approval, freely subscribe to the mailing list

all those among your friends who would like to be informed about

energy, the environment, and EFN's activities. To do this, just type

their e-mail address above, and click the "Subscribe" button (with

their approval).

To subscribe to our mailing list, the only condition is to share

our point of view and to type in your e-mail in the box above. You

will then be informed automatically of EFN's activities. This

subscription is entirely GRATIS. EFN is a not-for-profit

organization. It does not place any commercial advertisements on it's

web site, and does not sell it's mailing lists to anybody. To help

the EFN continue its activities, inform the public, and maintain this

FREE service, you can subscribe

or make

a donation to the association. Your donations are tax-deductible

in France. For subscriptions and donations intended for EFN-USA,

click

here (for our American readers and US citizens, donations in US$,

EFN-USA is a 501(c)(3) tax-exempt not-for-profit corporation). For

donations in Japanese Yens (for our Japanese readers), click

here.

©

EFN, all rights reserved - Unless

specifically mentioned otherwise, reproduction, use or distribution

of these information, texts or images, without EFN's prior written

approval, is forbidden

Photo

of the Mihama nuclear power plant seen from the nearby beach. The

accident took place in the turbine hall of reactor number 3 which is

the one on the right of this photo.

Photo

of the Mihama nuclear power plant seen from the nearby beach. The

accident took place in the turbine hall of reactor number 3 which is

the one on the right of this photo.

On

this photo taken on August 9th, 2004, one can see the steam rising

from the turbine building of reactor number 3 at the Mihama Nuclear

Power Plant in Fukui Prefecture. That steam comes from the inside of

the turbine hall,.which is the rectangular building on the left hand

side of the photo. The reactor itself containing the nuclear fuel is

located inside the circular-shaped concrete confinement in the center

of the photo. The nuclear reactor, the confinement building, and the

primary circuit were not affected at all by the accident. Mihama was

not a nuclear accident. The nuclear part of the installation was

unaffected. No radiation leaked and the reactor itself always

remained safe and under control.

On

this photo taken on August 9th, 2004, one can see the steam rising

from the turbine building of reactor number 3 at the Mihama Nuclear

Power Plant in Fukui Prefecture. That steam comes from the inside of

the turbine hall,.which is the rectangular building on the left hand

side of the photo. The reactor itself containing the nuclear fuel is

located inside the circular-shaped concrete confinement in the center

of the photo. The nuclear reactor, the confinement building, and the

primary circuit were not affected at all by the accident. Mihama was

not a nuclear accident. The nuclear part of the installation was

unaffected. No radiation leaked and the reactor itself always

remained safe and under control.

Berol

is the President the American association of Environmentalists For

Nuclear (EFN-USA)

Berol

is the President the American association of Environmentalists For

Nuclear (EFN-USA)